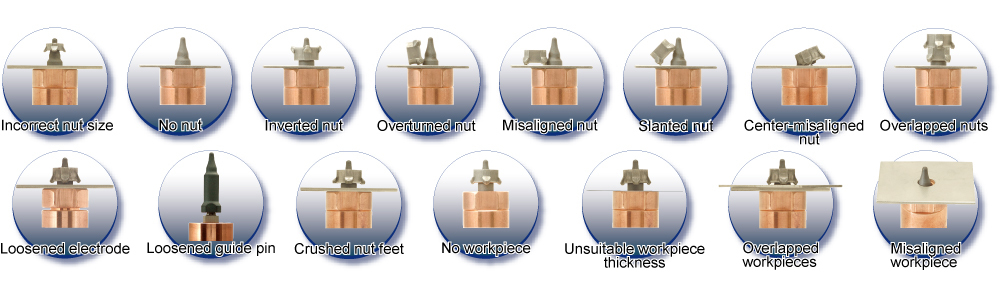

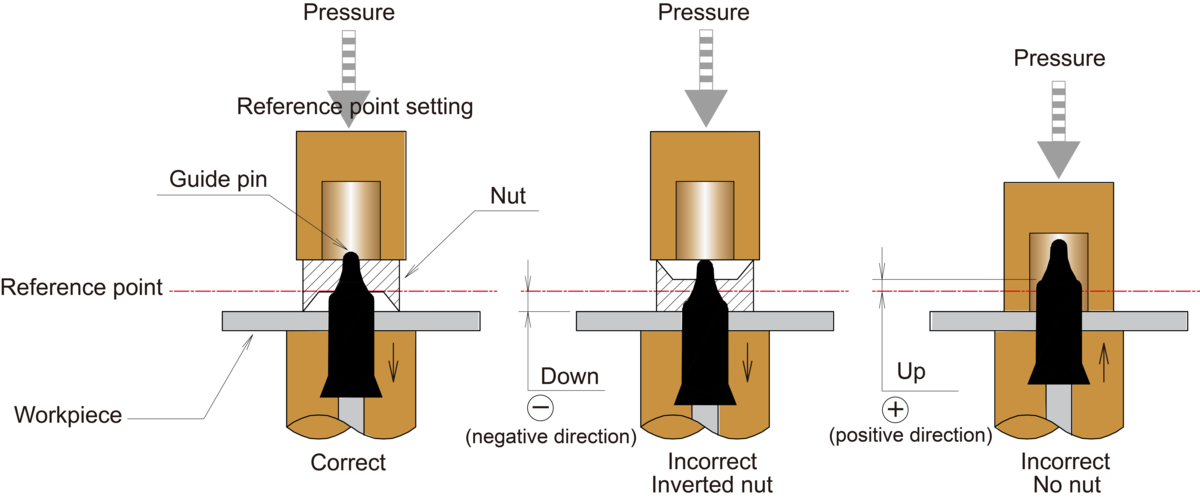

Examples of incrrect Nut Setting

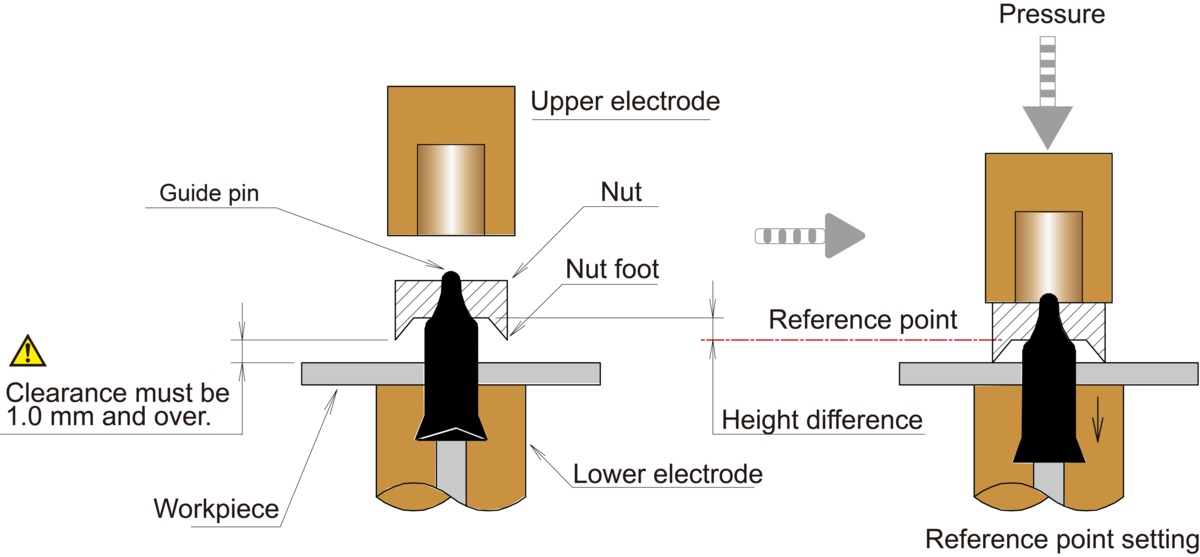

Method of Nut Detection

When pressured, the guide pin is pressed by the upper electrode to descend.

This height difference determines whether the nut is set correctly or not.

How to Detect Incorrect Nut Setting

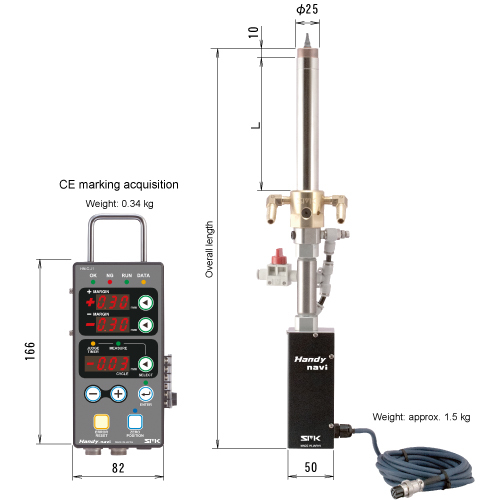

Handy-navi

Suitable for manual operation.

Workpieces are set manually. Suitable for operations feeding nuts manually or by nut feeder.

Φ32 holder = Nut size (M10.M12.7/16)

Overrall length=(425㎜.475㎜.525㎜)

L=(140㎜.190㎜.240㎜)

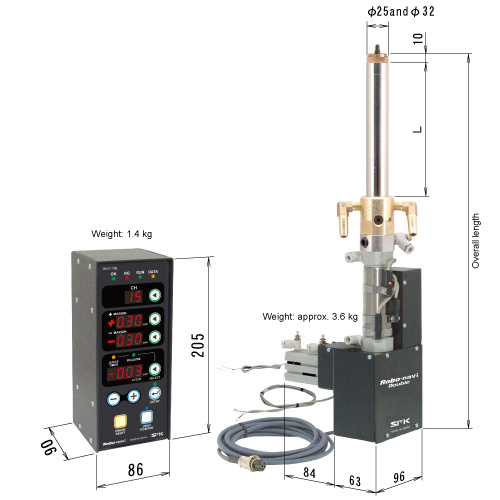

Robo-navi-single

Suitable for robots and automated machinery.

Suitable for fully automated welding system which uses controlling function and robot for workpiece setting, nut feeding, product-type switchover, changing weld conditions, etc.

Φ32 holder = Nut size (M10.M12.7/16)

Overrall length=(425㎜.475㎜.525㎜)

L=(140㎜.190㎜.240㎜)

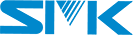

Robo-navi-Double

Suitable for robots and automated machinery.

Suitable for fully automated welding system which uses controlling function and robot for workpiece setting, nut feeding, product-type switchover, changing weld conditions, etc.

Φ32 holder = Nut size (M10.M12.7/16)

Overrall length=(423㎜.473㎜.523㎜)

L=(140㎜.190㎜.240㎜)