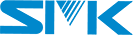

Examples of incrrect Nut Setting

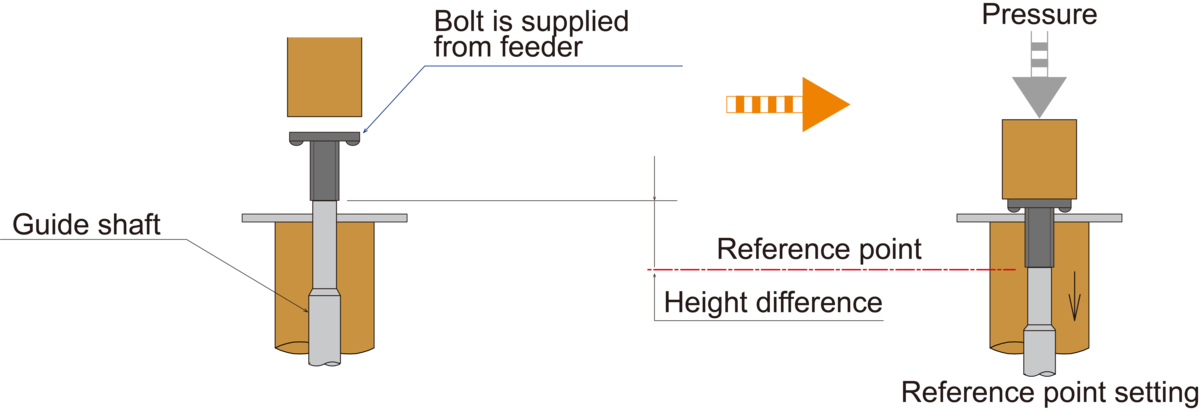

Method of Bolt Detection

Manual work specification

Bolt feeder specification

Handy-Robo-navi-Bolt

Suitable for manual operation(Bolt feeder spcification)

Φ25 holder = Nut size (M6.M8)

Φ32 holder = Nut size (M10)

Overrall length=(450㎜.500㎜.550㎜)

L=(140㎜.190㎜.240㎜)

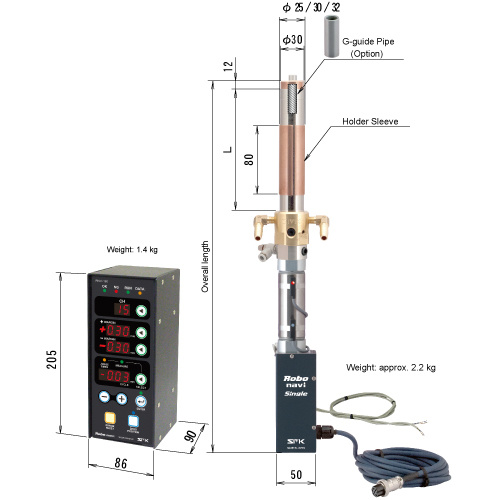

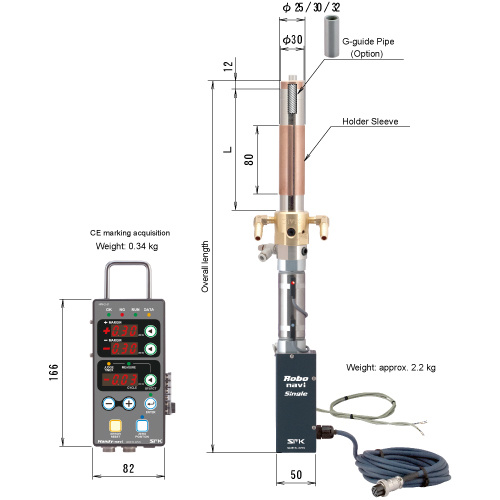

Robo-navi-Bolt

Suitable for robots and automated machinery(Bolt feeder spcification)

Φ25 holder = Nut size (M6.M8)

Φ32 holder = Nut size (M10)

Overrall length=(450㎜.500㎜.550㎜)

L=(140㎜.190㎜.240㎜)